The key to system and process safe operation is the ability of operators in industrial fluid management to quickly see what phase their media are currently at. The Sight Glass is a specially designed pipeline observation window enabling operators to confirm flow direction, identify turbulence and visualize air or particulate presence. The intention of this visual indicator is to offer the most transparency yet still be pressure system tight. Instead, a this aspect of monitoring is optimsic clarity-check and comprises only engineered applications to maintain the visibility in even rowdier environments as well.

To meet various installation needs, the units come in multiple configurations - cross-type and tube-type designs . Using a high-performance Sight Glass can offer facilities and non-intrusive diagnostic means, without the need for manual sampling or bringing systems down. This equipment is an essential component of modern industrial infrastructure and helps to visualize the fluid stream dynamics that are not visible otherwise.

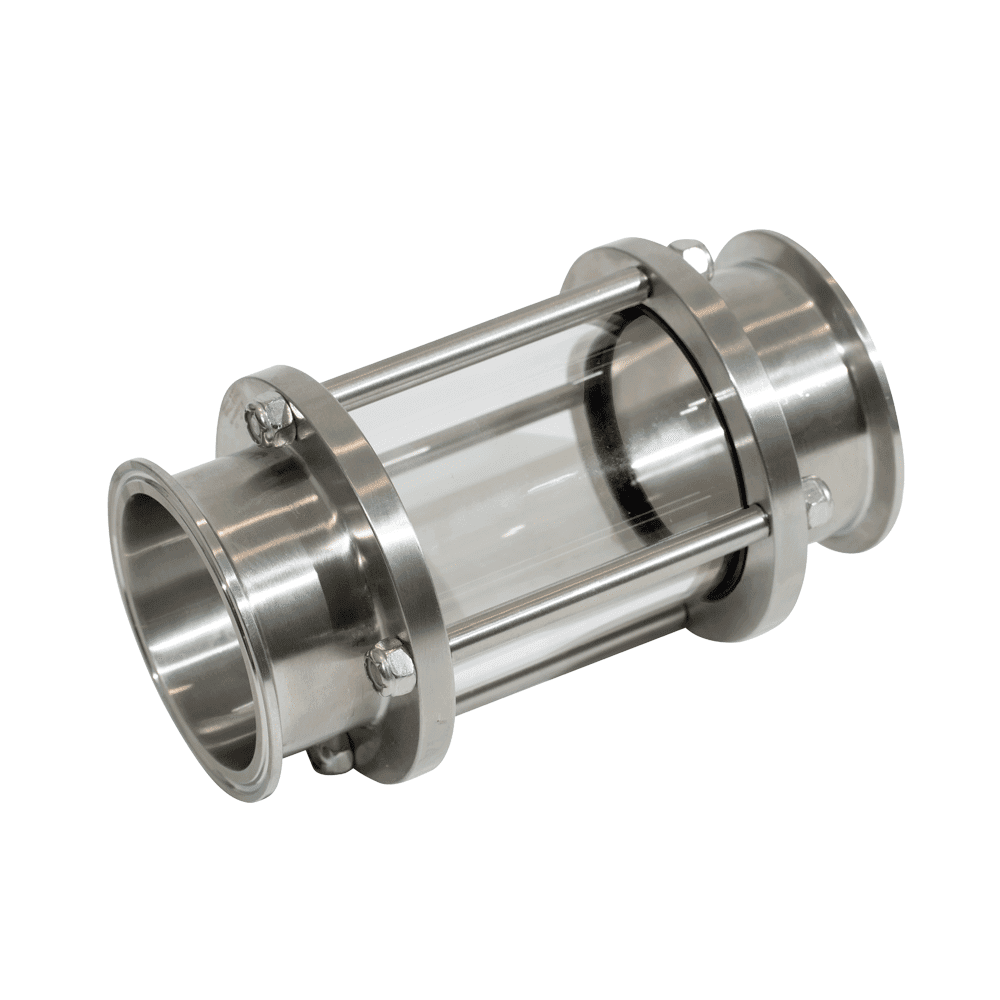

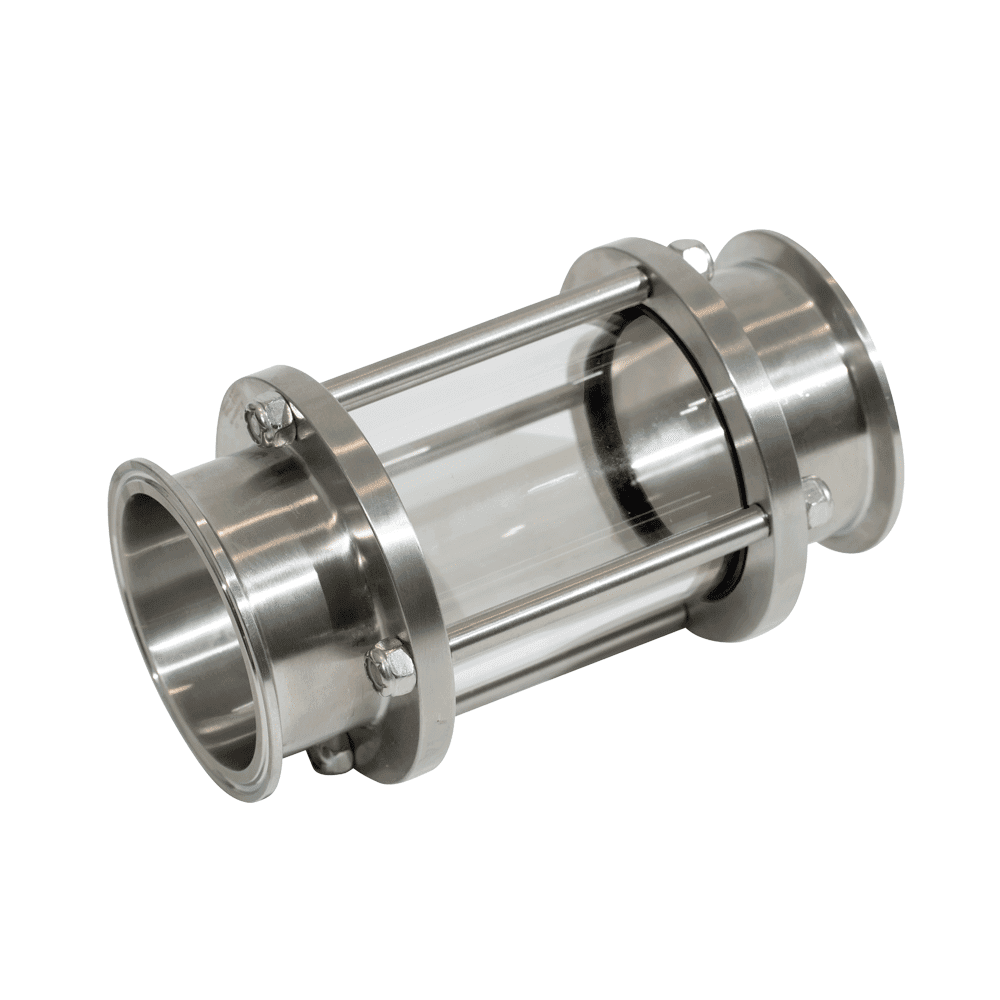

The operational value of the Sight Glass is derived from its simple yet robust construction, which balances optical quality with mechanical strength. The device functions through a high-strength transparent section that is securely housed within a protective body. This internal chamber is designed to match the diameter of the connecting pipes, ensuring that the fluid moves through the observation zone without significant pressure drop or flow restriction.

During operation, the Sight Glass relies on a precision-sealed interface where the viewing element is held in place by specialized gaskets. These seals prevent leakage and protect the transparent window from mechanical stress caused by thermal expansion or pressure surges. Because the internal bore is smooth and non-reactive, it resists the buildup of scale or biofilm, which ensures that the Sight Glass remains clear and functional throughout its operational life. This focus on long-term visibility makes it an ideal choice for monitoring sensitive chemical reactions or water purification stages.

These observation components are constructed from an array of innovative polymers, combined with high-grade glass, to ensure reliability across multiple industrial sectors. When it comes to raw material for the Sight Glass, and primarily choice depends on chemical composition and temperature of media transported:

UPVC and CPVC Options UPVC is common for general water treatment and moderate corrosive applications as it can work well upto 60degree celsius. CPVC – for the system with higher temperatures or more aggressive acids, CPVC is used so that thermal stability can be secured up to 95 degrees Celsius. These practices are designed to keep the housing immune from external oxidation and internal chemical breakdown.

PPH and PVDF Design: We have chosen PPH for its high resistance to impact, you choose this Media piping the Alkaline Lot Rate Max only 95 degrees C. PVDF is also common for use where material compatibility with silicon or very aggressive halogens are of concern and PVDF often finds its home as the preferred Sight Glass in the most challenging environments such as semiconductor fab, utility scale concentrated solar power systems mining industries among others. Providing an increased range of applications (-40 to 120C) and unsurpassed purity (no contaminants leached into the fluid stream), PVDF is in a class by itself.

The viewing window, itself, is normally made of borosilicate or tempered safety glass. They are resistant to thermal shock & chemical attack so the Sight Glass can withstand sudden increases in temperature without breaking.

Here are the technical advantages of integrating a Sight Glass into your piping network:

Superior Corrosion Resistance: A polymer Sight Glass is impervious to corrosion of any kind as opposed to a metallic sight glass that will eventually rust and suffer from galvanic corrosion. This is especially advantageous in moist, saline or acidic surroundings where metal components would need frequent painting or replacing.

Simpler Troubleshooting: The Sight Glass enables maintenance teams to quickly diagnose system problems such as pump cavitation, valve malfunction or filter buildup. The QD shows an image of the failure from a test pressure higher than 210 bar, which increases diagnosis time and can lead to catastrophic equipment damage. The Sight Glass provides immediate visual feedback in real operation so problems are caught before they become critical events .

Easy Installation & Light weight construction: An advanced plastics design makes the support lighter and easier to install. With the majority of models offering standard flanged, socket or threaded ends this makes integration into existing plastic and metal piping systems simple.

| Component | Standard Materials | Performance Advantage |

|---|---|---|

| Main Housing | UPVC, CPVC, PPH, PVDF | Total corrosion immunity and high strength |

| Viewing Window | Borosilicate / Tempered Glass | Exceptional clarity and thermal resistance |

| Sealing Gasket | EPDM, FPM (Viton) | Reliable hermetic seal and chemical stability |

| External Fasteners | Stainless Steel | Prevents rust in outdoor or humid conditions |

| Connection Types | Flange, Socket, Threaded | Versatile fit for various piping standards |

The versatility of the Sight Glass makes it an indispensable tool across many specialized technical fields:

Request a Quote